Watrec OY

Watrec is a Finnish environmental engineering company that specialises in economically and environmentally sustainable waste-to-energy solutions.

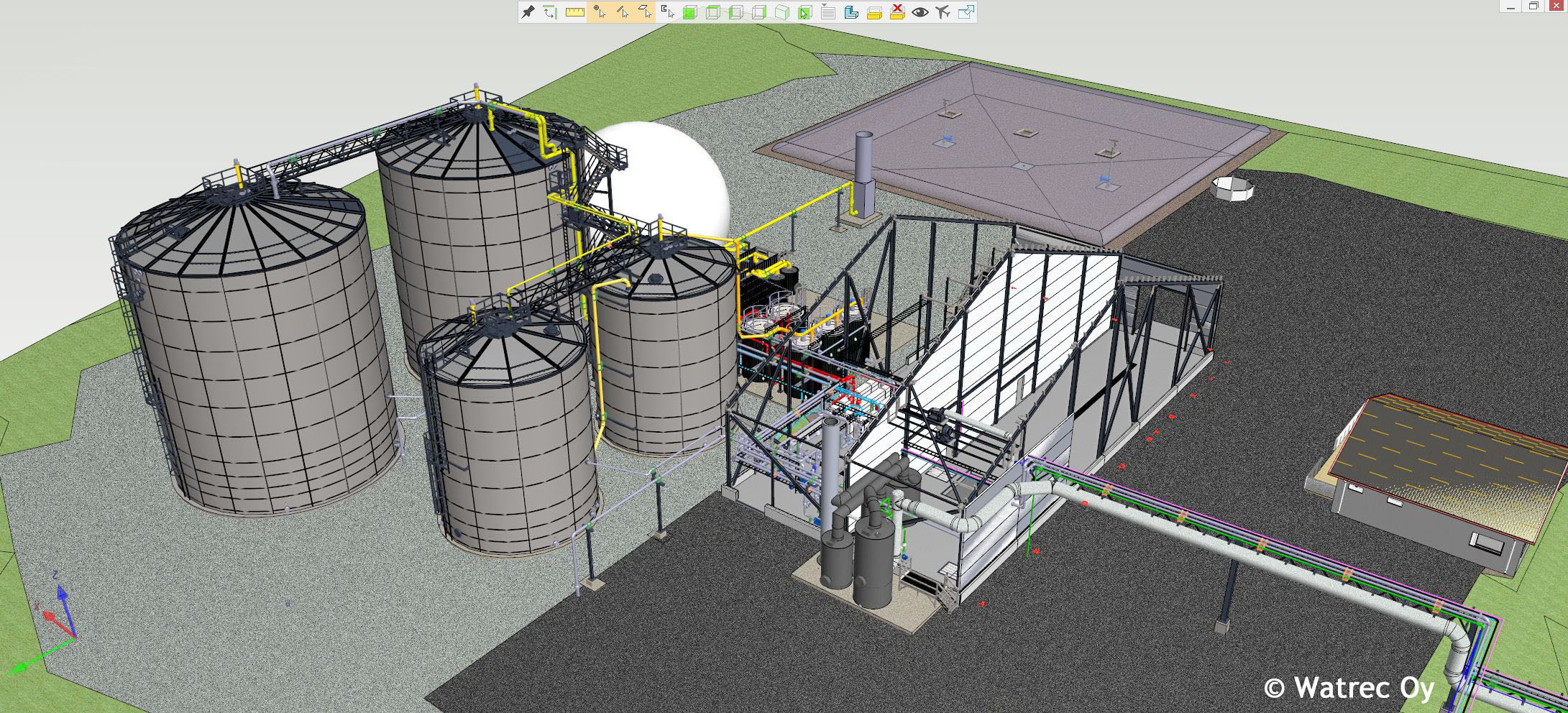

Vertex G4Plant and Vertex Flow software assist in plant design and information management.

*This case study has been translated from Finnish to English. The original story can be found here Watrec Oy – Vertex G4Plant

The leader of biogas technology grows rapidly

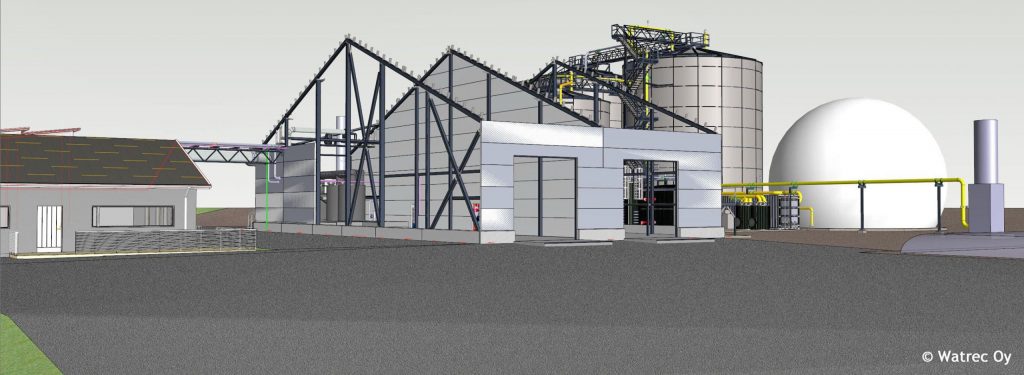

Watrec designs and builds biogas plants that convert organic waste into renewable energy and produces high-quality fertiliser as a by-product. Biogas is used in heat and electricity generation and the fertiliser is used primarily in agriculture.

In 2003 Watrec started off as a one-man consultation business in Forssa, a town located about 120km north from Helsinki. Two years later, the first Watrec designed biogas plant was completed in Vehmaa in the south-west coast of Finland. Within a decade, the company had fully established itself as a major bio-energy plant producers employing 20 people in their two locations in Forssa and Jyväskylä, with a yearly turnover of 8-15 million euros.

Watrec has been awarded for their progressive design, project management and for their plant security and control systems. They were also noted on the environmental industry’s Best Practice list in 2007. Since the company’s first plant in Vehmaa in 2005, Watrec has expanded and built biogas plants in six cities around the country.

“We took total responsibility of our third plant. As the main designer, we took care of architectural, process, mechanical and piping design. That is when we made the decision to also build the plants ourselves. This increased our annual turnover to the million-category”, Watrec Oy solutions director Juha-Pekka Sura said.

Mr Sura leads the company’s business unit, acts as a project design manager and is in charge of manufacturing. He has been working with Watrec since 2007.

“We put effort into long customer relationships. It is important to us to design and build technologically reliable plants that are at the same time economically productive as well as environmentally sustainable that will secure a cleaner environment for the future. Seventy-five per cent of our resources are of Finnish origin.”

Watrec is the market leader in the biogas plant industry in Finland. While there is still room for a few more plants locally, Watrec is looking to expand into overseas markets such as Greece, South East Asia and Mexico.

Due to the growth, Watrec is now recruiting new plant designers.

The right software for large projects

Watrec implemented Vertex G4Plant software solution in 2013.

“The deciding factor was G4Plant’s easy to use piping design. We also use Vertex Flow to support G4Plant, as well as in all our project management. We have many overlapping projects and previously we found it difficult to manage all the documentation and drawings,” Mr Sura said.

Watrec’s projects are extremely large. The filed physical documents for one project would create approximately 20 folders of paper. Mr Sura praises G4Plant’s data compatibility, useful piping tools and extensive libraries.

“G4Plant is customised to our needs which makes design work easy. We have been very pleased with the quick response time from Vertex. Support is usually instant. We are also thinking of implementing Vertex Building Design software in our business,” Mr Sura said.

This is how a biogas plant works:

- Biogas is generated when organic waste biologically decomposes in anaerobic conditions.

- The biogas plant uses waste as its raw material, which is collected, for example, from wastewater treatment plants or the food industry.

- The organic material is digested, resulting in both biogas and fertilizers.

- About two-thirds of biogas is methane and one-third is carbon dioxide.

- Biogas can be used as a fuel for heat production in gas boilers. It can also be burned in a gas engine to produce heat and electricity. In addition, biogas can be refined into a transportation fuel.