Helena Lidelöw: Steering VBC to global success with Vertex BD software

VBC grows with a core strategy centred on customisation and flexibility in Vertex BD, guided by Helena Lidelöw.

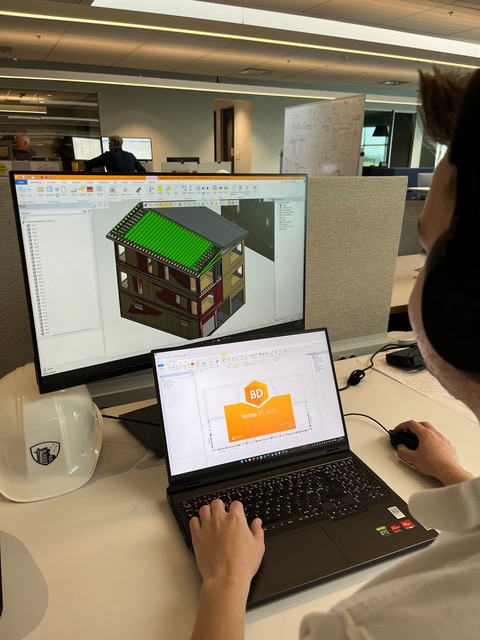

Built Offsite’s publisher, Michael Dolphin interviewed Helena Lidelöw, CTO of global modular manufacturer VBC about Vertex BD software solution.

Helena Lidelöw’s journey in the dynamic field of offsite manufacturing, particularly her instrumental role in integrating Vertex BD software at the U.S.-based global modular builders VBC, epitomises innovation, adaptability, and a global strategic vision. (main pic: VBC’s Tracy modular manufacturing facility in California.)

Prior to joining VBC in January 2022, her career blended academia and industry expertise. She played a significant role at Luleå University of Technology in Sweden, researching and developing building systems for industrialised construction, a position she held until 2016. During this period, she also co-launched the new factory at Lindbäcks Bygg, one of Sweden’s most progressive modular multi-family building companies.

During her 12-year tenure at Lindbäcks Bygg, she led the R&D and Design team, striving to balance standardisation and flexibility in the company’s manufacturing processes, effectively converting theories into practical industry applications. A crucial realization emerged at Lindbäcks Bygg: to succeed, a modular builder requires software that engages with project designers and successfully translates and implements that vision into the modular builder’s processing machinery.

The need for a software solution became evident when the limitations of the company’s existing software were exposed. As Helena noted, “At Lindbäcks we were running a type of two-dimensional software, and the software’s inability to fully integrate with advanced 3D modelling and clash detection systems, necessitated the search for an alternative.”

After extensive trials and exhausting all viable software alternatives, she recalled, “It became very evident that other software was not ‘strong’ enough to support all the operations we wanted.”

Helena and her team found the solution in Vertex BD, an advanced software for efficient building design and construction, which also optimised the company’s modular construction processes.

Helena Lidelöw – Chief Technical Officer at VBC

Following her appointment at VBC in 2022 as Chief Technical Officer, her experience with software, including Vertex BD, was vital in guiding the design team at VBC in the U.S. The decision was made to transition to Vertex BD for all their wood-framed manufacturing assets for their operational needs. She emphasised, “We’re now running Vertex BD for all framing.”

However, the process of transitioning to Vertex BD was complex. Integrating software with automated machines is a demanding task. Helena pointed out, “Nothing is straightforward in this route because when you’re dealing with automated machines, you have to understand that they are not off-the-shelf products.” The challenges involved required careful negotiation and a deep understanding of the unique nature of these systems. Here, according to Helena, Vertex’s supportive role was crucial in managing these complexities.

“It comes down to how much support you can get from the team. And I believe Vertex BD has been very helpful to get us where we need to be and working in tight connection with our internal team that we have grown in parallel,” said Helena.

Vertex BD’s compatibility and customisation

The key to identifying efficiency dividends for VBC’s diverse manufacturing assets is understanding the nature of the product and the extent of software customisation required.

In cases where products are fully standardised, efficiency dividends can be achieved quickly, as only one round of scripting for a machine may be necessary, with no further adjustments or design processes needed.

However, at companies like VBC, where products are highly customised and may not have a standard catalogue of manufactured elements, a design-for-manufacturing approach is essential for each project. “You have to design for manufacturing every time. Then you have to look at the capabilities of the software to achieve this, and that’s what we looked at foremost. It’s an interplay between your business idea and your manufacturing capabilities,” said Helena.

She explained, “What you need to look at is what’s your product and how much you need to tamper with the software to get to the result you need.” At VBC, high degrees of customisation are necessary, lacking a catalogue of standardised modules, demanding a design-for-manufacturing approach for each project, which Vertex BD can accommodate.

The ability to customise Vertex BD and implement it across VBC’s global locations was key, as Helena highlighted the software’s diverse applications. She detailed, “For Tracy, California, it’s going to be feeding the machines with the machine files… For Berwick, Pennsylvania, I don’t have any automation… And for Poland, where I don’t do wood at all, I have steel. We define a Vertex BD environment that communicates what each location needs”

Vertex BD’s library function

A core feature of Vertex BD is its library function, which allows for the pre-definition of structural elements like walls, floors, roofs, beams, and connectors. These elements can be accessed for specific projects and facilitate the creation of flexible yet consistent patterns across different sizes and designs.

However, in addition to Vertex BD’s core library features, the software’s adaptability is also crucial in managing complex, custom manufacturing processes. Helena said, “If you have framing around a window, and you want to frame around that window a certain way, but the window has a different size. With Vertex BD, there is a ‘Smart Models’ command, for example, ‘I’m going to apply the ‘blue ball’ here, and the ‘blue ball’ will tell me that, okay, I need one king (vertical framing component in a wall), I need a jack (vertical stud), I need a header (horizontal structural member), and it’s going to be this many cripples (short vertical studs placed above or below a wall opening)’, and then it will just repeat the pattern every time it comes to an opening, regardless of opening size.” It is this adaptability that’s crucial in managing complex, custom manufacturing processes for VBC.

This command automates the replication of the framing pattern for different openings, ensuring consistency while allowing for size adjustments. Additionally, this feature enables users to work with a ‘kit-of-parts’ approach, which combines pre-defined elements with the flexibility to make adjustments.

“It’s a very useful feature, and you can ‘play this’ along the entire structure. It means that you can have your kit-of-parts, not only as a predefined solid thing, but you can also have a little bit of flex in that as well.”

The interplay between each of VBC’s global manufacturing assets and operational needs is significant. ‘Vertex BD has the compatibility and customisation we need to achieve this,’ concluded Helena.

See: https://www.vbc.co/“